Rongbai Achieves Breakthrough in Lithium-Rich Manganese Materials

Advertisements

In a recent development that could have a significant impact on the battery industry, breakthroughs have been achieved in the key technology related to lithium-rich manganese-based materialsThis advancement heralds the dawn of a new era characterized by the 'manganese-lithium' paradigm, which is poised to shape the future of energy storage solutions.

According to statements made by Rongbai Technology on their investor interaction platform, the company expresses strong optimism regarding the application of lithium-rich manganese-based materials in solid-state battery technologiesCurrently, their lithium-rich manganese cathode materials are undergoing sample testing, having reportedly achieved significant breakthroughs in key technical indicators at client sites, reflecting continued leadership in technological advancements.

Lithium-rich manganese materials are classified as high-voltage cathode materials, making them suitable for use in solid-state battery systems that feature a wide electrochemical window

This capability enhances their potential deployment in cutting-edge energy storage applications, particularly in electric vehicles and renewable energy systems.

Rongbai Technology has collaborated closely with various mainstream domestic and international cell and machine manufacturers to ensure that their sample performance remains at the forefront of client tests, solidifying a robust competitive advantage in the market.

So, what exactly constitutes lithium-rich manganese materials?

Lithium-rich manganese-based cathode materials are primarily developed by increasing the manganese content in lithium manganese oxide systems, forming stable solid solutions

- Volatility Grips Global Financial Markets

- Positive Outlook for Japan's Stock Market in 2024

- Volkswagen May Close Some Factories in Germany

- Asian Markets Boosted by Holiday Cheer!

- Impact of Interest Rate Differentials on the Forex Market

Through component design, ionic doping, and surface coating technologies, a layered composite structure is created to leverage the benefits of manganese-based cathode materials, including high voltage and low cost, ultimately enhancing battery energy density.

Current testing indicates that lithium-rich manganese materials exhibit a high specific capacity exceeding 250 mAh/g, significantly surpassing the capacity of commercially utilized lithium iron phosphate materials, and approaching that of high-nickel ternary materials in terms of discharge capacity.

Cost-wise, lithium-rich manganese materials reduce the inclusion of scarce metals such as cobalt and nickel compared to commonly used lithium cobalt oxide and nickel-cobalt-manganese ternary cathode materials, thereby significantly lowering material costs.

Furthermore, due to their excellent cycling stability at conventional voltages, lithium-rich manganese materials can achieve 2300 cycles without degradation under 1C charge and discharge conditions, and maintain over 88% capacity retention after 1700 cycles at elevated temperatures

This translates into improved low-temperature performance and safety for lithium batteries.

These materials have versatility; they can be utilized independently as cathode materials or in combination with other cathode materials, finding applications across various sectors, including electric vehicles, small electric devices, energy storage, and digital equipmentAdditionally, the high-voltage characteristics of lithium-rich manganese materials harmonize with the wide electrochemical window of solid-state battery systems, making them an ideal choice for solid-state battery cathodes.

Currently, companies like Rongbai Technology, Ningbo Fuli, Ningxia Hanyu, CATL, and Anshun Technology are venturing into the domain of lithium-rich manganese cathode materials

However, challenges remain, including initial charge-discharge efficiency, discharge rates, and cycling stability, indicating that lithium-rich manganese cathode materials are at a pivotal stage in the transition from research and development to industrial mass production.

On December 12, Rongbai Technology announced via their investor platform that their lithium-rich manganese cathode materials are currently in the sample delivery phaseThey have reportedly achieved breakthroughs in key technical indicators, reinforcing their leading position in technologyIt is noted that lithium-rich manganese cathodes are one of the materials capable of harnessing the high energy density advantages of solid-state batteries.

Prior to this, the company highlighted in their 2024 semi-annual report that they are continuously refining the preparation technology for various types of solid-state electrolytes, high-voltage nickel-manganese, lithium-rich manganese, and lithium-supplementing agents

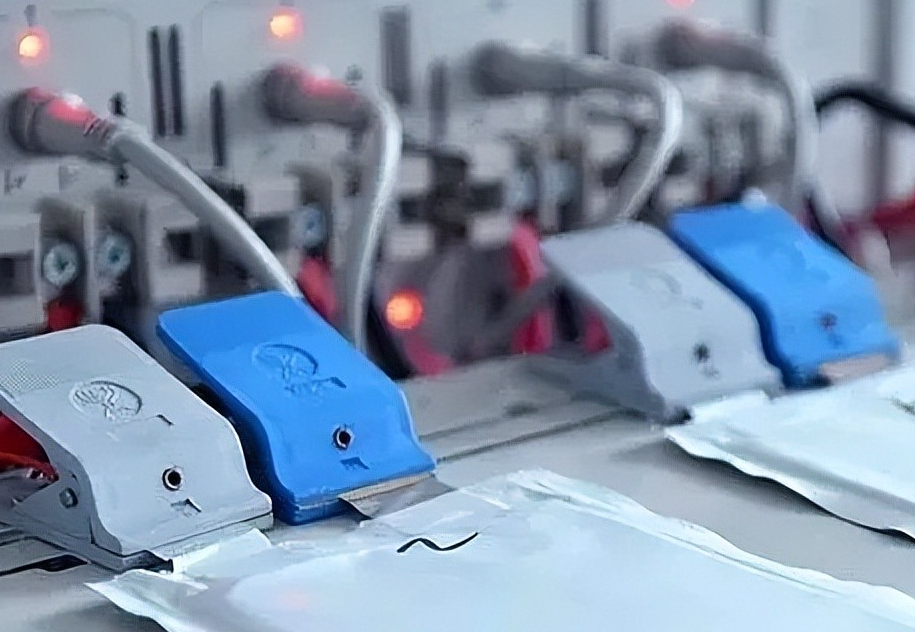

Their advancements encompass cutting-edge products like spinel nickel-manganese cathodes and lithium-rich manganese cathodes, spanning various industry sectors, from engineering equipment and testing to recycling, electrodes, and batteries.

As part of their future strategy, Rongbai Technology intends to improve rate performance and mitigate voltage degradation during the cycling and storage processesIf these technical challenges can be resolved, lithium-rich manganese cathode materials could emerge as highly promising candidates for the next generation of lithium-ion battery cathodes, finding widespread application in automotive, energy storage, small electric devices, and digital technology sectors.

Rongbai Technology has reported notable progress in the research and development of lithium-rich manganese materials, with key technical breakthroughs achieved at client sites

Their low-cobalt long-cycle lithium-rich manganese cathode materials have been developed through close collaboration with numerous prominent domestic and international cell and machine manufacturers, maintaining a competitive edge in regards to capacity and cycling performance during client tests.

Looking ahead, as the drive for high-performing and cost-effective lithium batteries continues to intensify within the new energy vehicle and energy storage battery markets, manganese-based cathode materials, whether from lithium manganese oxide systems or lithium manganese iron phosphate, are expected to gain significant traction as preferred materials due to their high energy density and cost-effectiveness.

In summary, Rongbai Technology has set its sights firmly on the evolving landscape of lithium-rich manganese materials